Many products used in the automotive industry were manufactured with asbestos, a substance that put automotive workers at a high risk of asbestos-related diseases like mesothelioma. Thankfully, help is available. If you or a loved one was diagnosed with mesothelioma, our team can connect you to medical and financial resources.

Automotive Workers and Mesothelioma Risks

Automotive workers are responsible for repairing and manufacturing cars and other vehicles. Sadly, many automotive workers were exposed to asbestos through car parts, leaving them at risk of developing mesothelioma.

This is particularly true for military automotive workers. The U.S. military was one of the biggest consumers of asbestos, meaning U.S. veterans who served as automotive workers may especially be in danger of developing mesothelioma.

Thankfully, automotive workers can pursue benefits from the U.S. Department of Veterans Affairs (VA). These benefits include health care and monthly financial payouts. Learn more in our Free Veterans Packet.

Asbestos Found in Automotive Parts

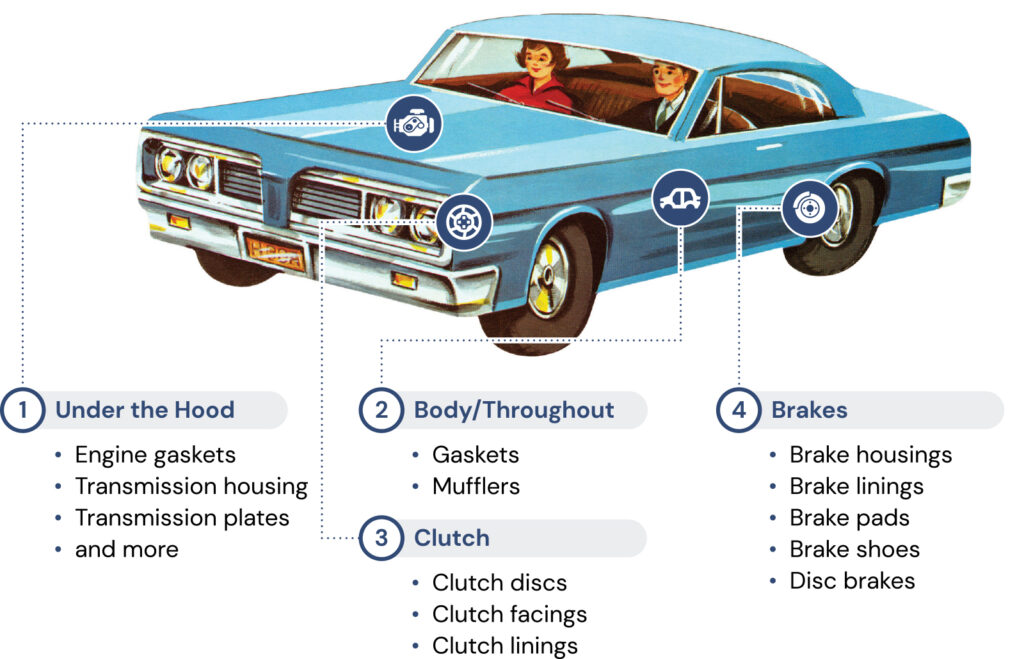

Automotive workers specialize in the building, maintenance, and repair of vehicles. Since friction is a big part of what makes an automobile function correctly, manufacturers once turned to asbestos to make products because it was both strong and fire-safe.

Car and truck parts that contained asbestos included:

- Brake linings

- Brake pads

- Clutch parts

- Gaskets

- Hood linings

- Insulation

- Transmission parts

- Valve rings

Auto workers were routinely exposed to asbestos when they repaired or replaced brakes, insulation, and other parts. When these parts wore down, asbestos fibers could be released into the air and inhaled or ingested by an automotive worker.

Asbestos exposure happened during automobile manufacturing, automotive repair, and the replacement of automobile parts. The dangers of asbestos weren’t made clear to automotive workers — but many manufacturers of asbestos-containing parts knew about the risks and hid them to protect their profits.

As a result, many products used in automobile manufacturing were made from asbestos until the early 1980s, when the risks became public knowledge and steps were taken to limit the use of this dangerous material.

Automotive Unions & Asbestos Exposure Risks

Automobile mechanics and other workers in the automotive industry who were part of a union might have been exposed to asbestos while working their trade.

Those who belonged to these unions were at a high risk of asbestos exposure:

- Delphi Chassis Kettering Operations

- General Motors in Ohio

- Indiana Local 907

- Indiana Visteon (workers in the Ford company)

- IUE-GM Delphi-Valeo-DMAX Conference Board

- Michigan Local 436A FW

- Meridian Automotive Systems in Michigan

- Moraine Assembly

- Ohio Local 755

- Ohio Local 798

- United Automobile Workers Union (UAW)

Families of Automotive Workers and Secondhand Asbestos Exposure

Family members of automotive workers are also at risk of asbestos-related illnesses, including mesothelioma. Automotive workers could unknowingly bring asbestos fibers home on their clothing, exposing their family members and loved ones. This is known as secondhand asbestos exposure.

For example, John, an English professor, was diagnosed with pleural mesothelioma in 2012. He'd never worked around asbestos, but his father had worked around asbestos-containing car brakes for three decades before his death from lung cancer. John's cancer was directly tied to secondhand asbestos exposure.

The team at Mesothelioma Veterans Center has helped many victims get help for their asbestos-related illnesses. Contact us today to learn how we may be able to support you.

Automotive Workers and Modern-Day Asbestos Risks

Unfortunately, even after the dangers of asbestos became known to the world, some workers continue to be exposed to this substance as part of their job.

When automotive workers service older or vintage vehicles, they may come into contact with parts containing asbestos. Automotive workers should always use respiratory equipment provided by their employer if they might have to work with asbestos-containing products to keep them safe.

High-Risk Jobs for Automotive Workers

Certain jobs and tasks put automotive workers at a greater risk of mesothelioma than others.

These high-risk tasks include:

- Engine repairs

- Cleaning brake drums

- Replacing brakes and clutch equipment

- Repairing or replacing gaskets

Thankfully, both military and civilian mechanics may be able to pursue benefits, treatments, and financial compensation following a mesothelioma diagnosis caused by asbestos exposure.

Assistance for Automotive Workers With Mesothelioma

If you served as an automotive mechanic and later developed mesothelioma, you may be entitled to compensation for your illness.

Thankfully, there are plenty of ways to get the help you deserve. Learn about your options below.

VA Benefits

If you're a U.S. veteran who served as an automotive worker, our team can help you access mesothelioma VA benefits. In almost all cases, veterans with mesothelioma receive a 100% disability rating, which is nearly $4,000 a month if you have a spouse.

Further, veterans with VA health care can get low-cost or free treatment from some of the best mesothelioma doctors who work at VA medical centers across the country.

File for mesothelioma VA benefits with our team's help today.

Legal Claims

You may be able to file a legal claim against the makers of asbestos-containing automotive products. These claims often award $1 million or more on average — without affecting your ability to get VA benefits.

For example, Ernie was a U.S. Army veteran who worked as an auto mechanic for decades both before and after serving. Late in life, Ernie developed pleural mesothelioma. Thankfully, by filing a private claim with the help of skilled lawyers, Ernie secured compensation to help pay for medical care and other expenses.

Connect with experienced attorneys to file a claim now.

Asbestos Trust Fund Claims

It's also possible to get compensation through asbestos trust funds. These funds were created by makers of asbestos-containing products that declared bankruptcy. More than $30 billion is currently available in these trusts.

You'll still be able to file for VA benefits if you file an asbestos trust fund claim. Our team can help determine if you qualify to file a trust fund claim.

Mesothelioma and Automotive Workers: Get Help Now

Mesothelioma in automotive workers remains a public health crisis, with more people being diagnosed each year. Due to this cancer's long latency period, many people exposed years ago are just getting sick now.

Thankfully, the Mesothelioma Veterans Center is here to help both veteran and civilian automotive workers get benefits, treatments, and compensation.

Our team — made up of U.S. veterans, VA-accredited staff, and caring patient advocates — will work with you every step of the way.

Contact us now to see all the ways we may be able to help you.

FAQs About Mesothelioma and Mechanics

Do mechanics get mesothelioma?

Yes. Before the mid-1980s, mechanics were often exposed to asbestos while installing, repairing, and replacing asbestos-containing car parts, putting them at risk of mesothelioma.

Since this cancer takes decades to develop, mechanics who were exposed to asbestos years ago are still at risk of getting mesothelioma today.

Do they still use asbestos in brake pads?

In most cases, no. The majority of manufacturers do not use asbestos in brake pads due to the risks this substance poses to automotive workers, according to Goodyear.

However, the U.S. Environmental Protection Agency (EPA) warns that automotive workers should use caution when working with brake components, as older vehicles may still have asbestos-based brake pads.

Which automotive mechanics are most likely to get mesothelioma?

Automotive mechanics who worked on or around cars, trucks, or other vehicles built before the 1980s are at the highest risk of mesothelioma today.

These mechanics likely worked with or near asbestos — the only known cause of mesothelioma — before the dangers of this substance were well-known.

How much compensation do you get for mesothelioma?

The amount of compensation you may get for mesothelioma depends on many factors, but the average mesothelioma settlement awards between $1 million and $1.4 million.

Compensation may also be available for automotive workers from asbestos trust funds and VA benefits.

Contact a mesothelioma law firm now to find out if you may be eligible for compensation.